Our vertical ribbon mixers and blenders are particularly targeted at the food industry and pharmaceutical industry, as they ensure good mixing and the absence of residues during emptying. They can also be used as homogenizers for powders of equal type but different lots.

Vertical ribbon mixers design

Gimat vertical mixers are characterized by a conical body with a special vertical axis ribbon screw.

Rotation of the helicoid blade creates two crossed flows, one of which is forced and the other gravitational, as follows:

- An ascending flow of the product in the external peripheral portion of the mixing chamber

- A descending flow at the center due to the effect of gravity.

The powder mixing is fast, homogenous and gentle, without overheating the mixed product.

The low peripheral speed makes these mixers particularly suitable for applications in hazardous areas in accordance with ATEX regulations 2014/34/UE e 1999/92/CE. ![]()

Main technical benefits

- The rotation of the mixing shaft is carried out by means of a bevel gearmotor that ensure a high output of the entire kinematic chain and quiet operation.

- Compared to common vertical screw mixers, in our vertical ribbon mixers the support of the mixing shaft is separate from the gearmotor allowing to change the latter without disassembling the mixing shaft, thus reducing maintenance time and costs.

- The mixing shaft is supported and centered only on the top of the mixer thanks to a ribbed die-cast food grade aluminum frame that comprises two robustly spaced large ball bearings. This solution creates an effective joint for the mixing shaft.

- The particular shape of the conical mixer body, allows a high quality of interior finish and ease of cleaning through its wide hatch. On request, they can be equipped with high pressure washing nozzles.

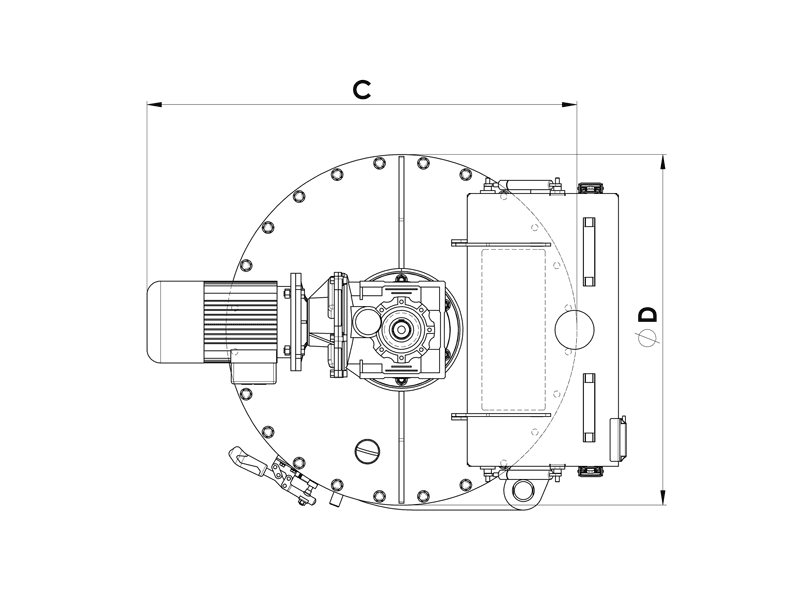

STANDARD VERTICAL MIXER MODELS AND DIMENSIONS

| Model | Geometric vol (lt) | Useful volume (lt) | Max load (kg) | Power (kw) | A | B | C | D | E |

|---|---|---|---|---|---|---|---|---|---|

| VMX 100 | 105 | 100 | 100 | 1,5 | 654 | 970 | 890 | 720 | 200 |

| VMX 200 | 230 | 200 | 200 | 2,2 | 658 | 1255 | 970 | 720 | 200 |

| VMX 340 | 430 | 340 | 340 | 3 | 808 | 1405 | 1045 | 920 | 200 |

| VMX 600 | 650 | 600 | 600 | 5,5 | 1008 | 1720 | 1330 | 1150 | 200 |

| VMX 1000 | 1200 | 1000 | 1000 | 7,5 | 1108 | 2020 | 1330 | 1250 | 250 |

Given the complexity of industrial mixing, in addition to the standard models we design and manufacture tailor-made vertical ribbon mixers and blenders.

Not sure what kind of powder mixer you need? Check our introduction to powder mixing equipment.

RELATED PRODUCTS

Have a look at our YouTube channel to find examples of our machines and turn-key plants

Example of applications of Gimat vertical mixers

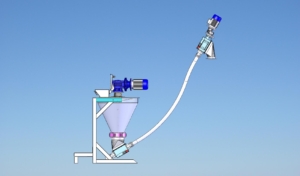

Powder mixing system with adduction of liquid aroma by membrane pump and lump breaker to spread the aroma while preventing the formation of lumps in the powder Emptying and movement without demixing the contents by means of a grooved screw conveyor on wheels in easy cleaning version

600 lt vertical ribbon mixer with double chopper/lump breaker on the sides for mixing fertilizers in hygroscopic powder form

Fed by gravity from a screw doser-filler for bags and cans of blended mixture. Logic control panel integrated in system.

340 usable liter vertical ribbon mixer for food and pharma sector, sandblasted exterior and internal polish. Can be filled manually or in a vacuum. With its cylindrical-conical design, it lends itself integrated operation as a pneumatic conveyor, cyclone and powder mixing unit. It has a lump breaking chopper to intensify the quality of the blend and prevent the formation of lumps during the addition of nebulized liquids.

50 to 200 lt vertical ribbon mixer designed for manual filling with hood to trap and capture any particulate generated during bag emptying.

Transfer of the blend obtained with flexible screw conveyors without demixing the contents.