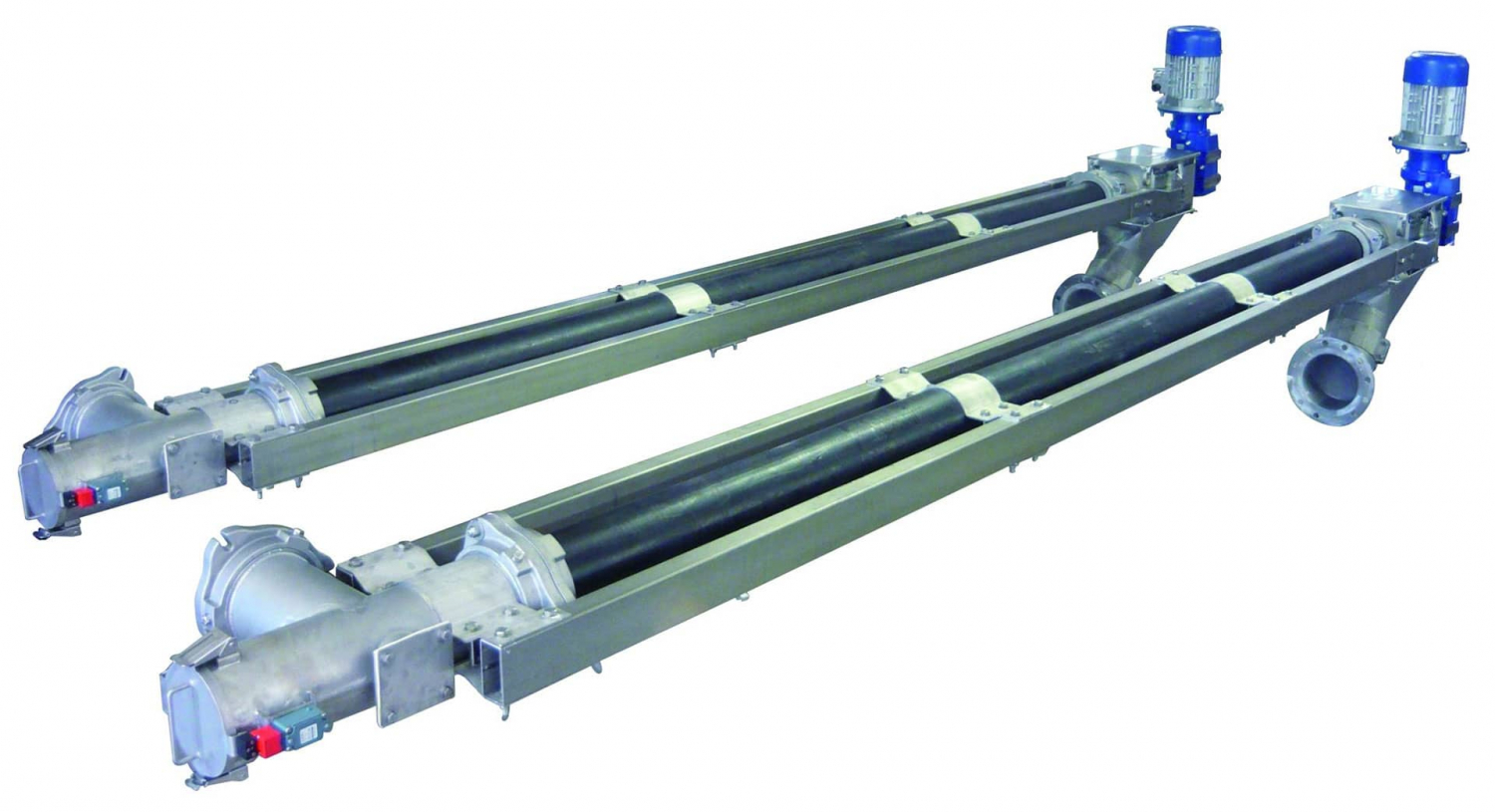

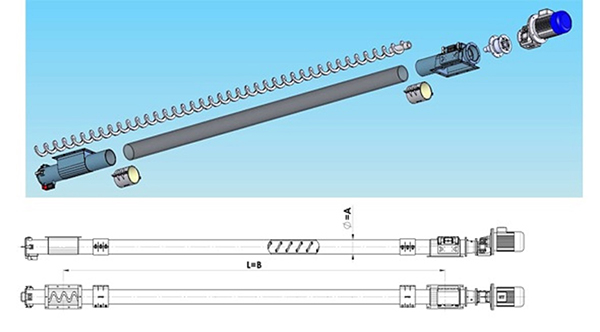

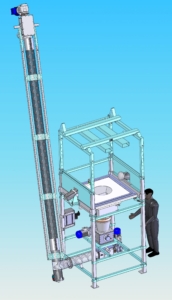

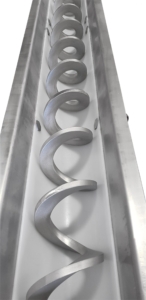

The shaftless screw conveyors are a high capacity and efficient conveying system for powders, granules, grounds and blends.

This new conveyor system was designed to implement the well-known flexible screws produced by GIMAT and widely acclaimed by the market since as far back as 1975, when much higher capacities were required or there was a need to move hard-to-convey products while maintaining as many as possible of the advantages of the flexible screws.