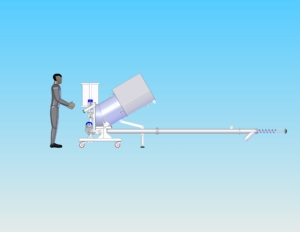

This powder transfer system is particularly suitable for high capacity loads at low angular speed. An auger conveyor is made of a screw that rotates around its own axis, thereby exerting an axial thrust on the material contained in the conveyor tube.

What are the main advantages of a screw conveyor?

- High flow rate;

- Suitable for horizontal, inclined and even vertical travel (elevator);

- Loading and unloading at any point of the line;

- Self-support between the two bays;

- Suitability for conveying products with high temperatures;

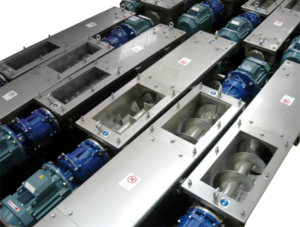

- Stainless steel versions perfectly suitable for conveying chemicals, pharmaceuticals or food products;

- Free of powder dispersion;

- Durability;

- Conveyed product can be cooled in cases of spiral conveyors made without outer jacket for containing coolant.

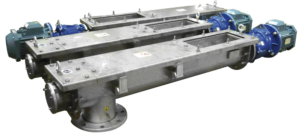

Auger conveyor design

GIMAT screw conveyors are built to customer specifications (for approximate indications see the table attached hereunder to identify the configurations possible), with particular care and attention as regards protecting from particulate all the bearings of the drive and thrust-bearing units and any intermediate supports, in case of conveyors longer than 4-5 mt.

In this connection, GIMAT has developed for the drive and thrust-bearing units a special dust seat with a greasable packing, with automatic recovery of any slack created during operation.

In this way, the packing give optimum performance at all times, ensuring a perfect seal on the rotating shaft of the screw.

This system reduces the number of manual adjustments that the traditional sealing systems require and also minimizes the annoying and hazardous powder leaks that reduce the duration of the bearings.

The intermediate support of the mechanical conveyor is made with a special self-lubricating material that is FDA-approved for contact with food; it has frontal seals, and a preloading device, made according to GIMAT design.

We manufacture our screw conveyors in stainless steel 304 or 316, and on request in painted carbon steel.

Upon request the flexible screw conveyor can be designed and built in conformity to ATEX Directive ATEX 2014/34/EU for Zone 2 – 22 and Zone 1 – 21 ![]()

| Model | External Diameter | RPM Max | Output (mc/h) | Bulk Density (kg/mc) | Output (kg/h) |

|---|---|---|---|---|---|

| TC.129/100 | 129 | 180 | 3,66 | 0,6 | 2200 |

| TC.139/100 | 139 | 180 | 6,66 | 0,6 | 4400 |

| TC.154/130 | 154 | 180 | 8,33 | 0,6 | 5000 |

| TC.168/140 | 168 | 180 | 10,33 | 0,6 | 6200 |

| TC.219/180 | 219 | 160 | 21,66 | 0,6 | 13000 |

| TC.273/250 | 273 | 130 | 41,66 | 0,6 | 25000 |