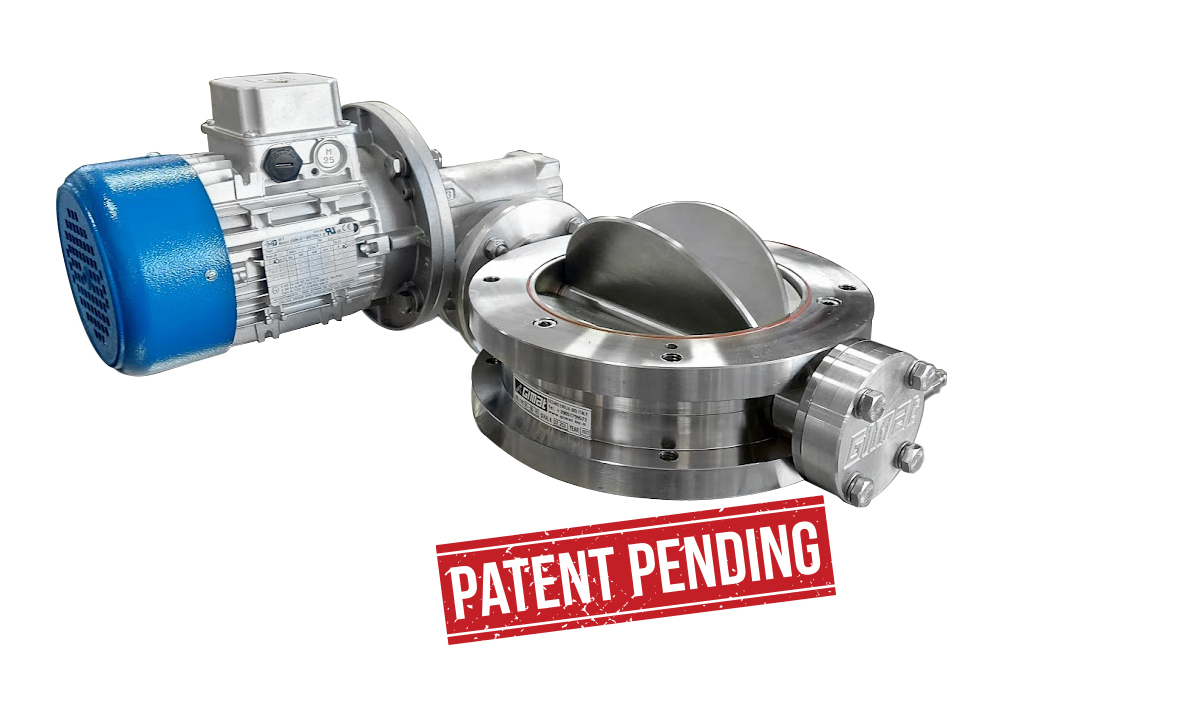

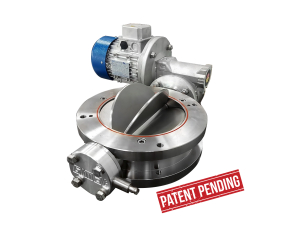

Gimat recently introduced a line of rotary valves – rotary feeders, patent pending, to include in its installations or sell separately, in accordance with ATEX directive 2014/34/UE and MOCA 1935/2004.

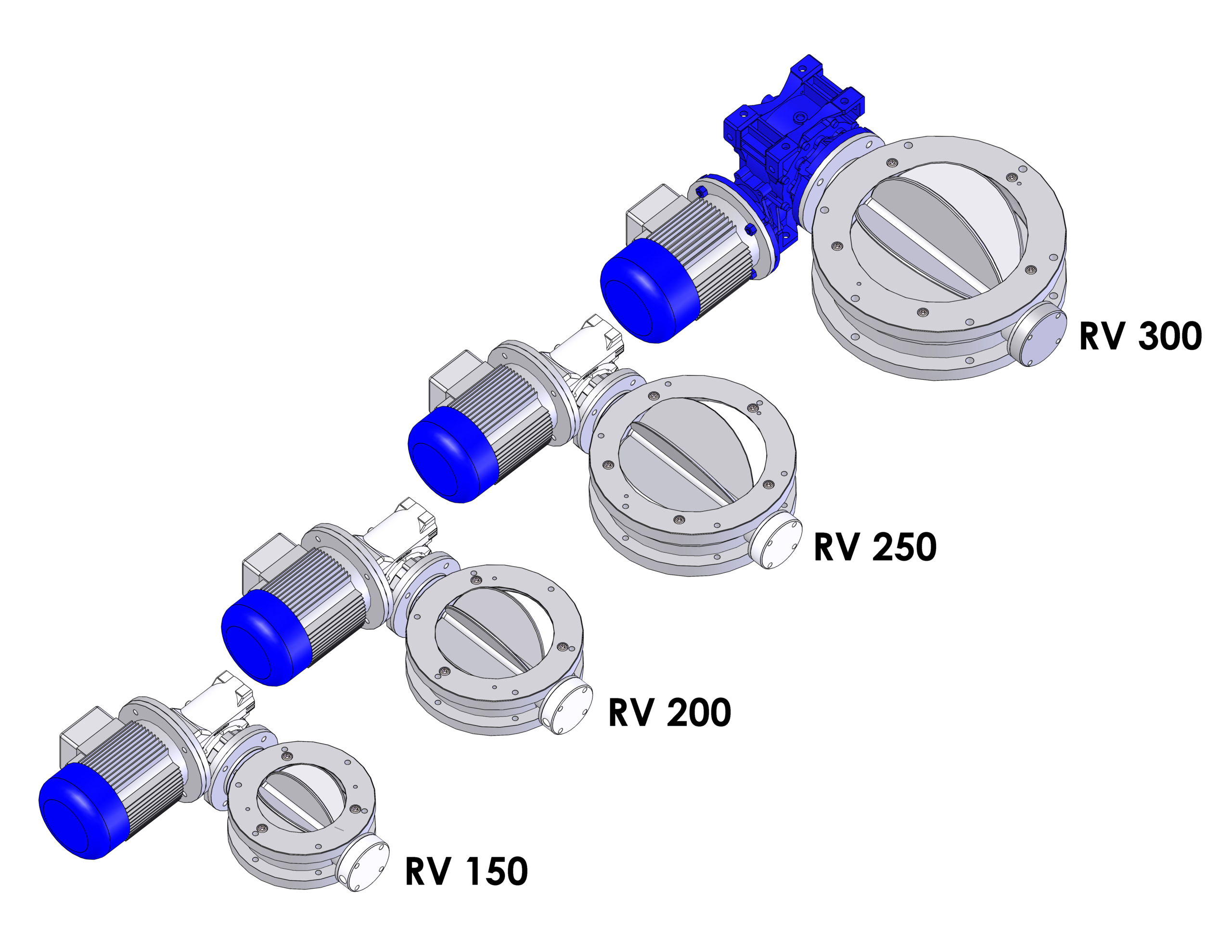

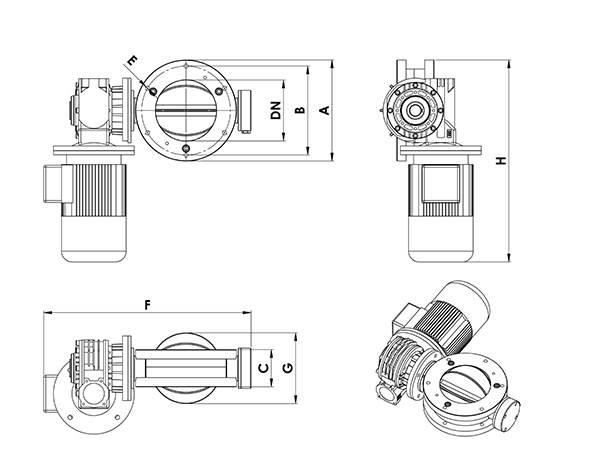

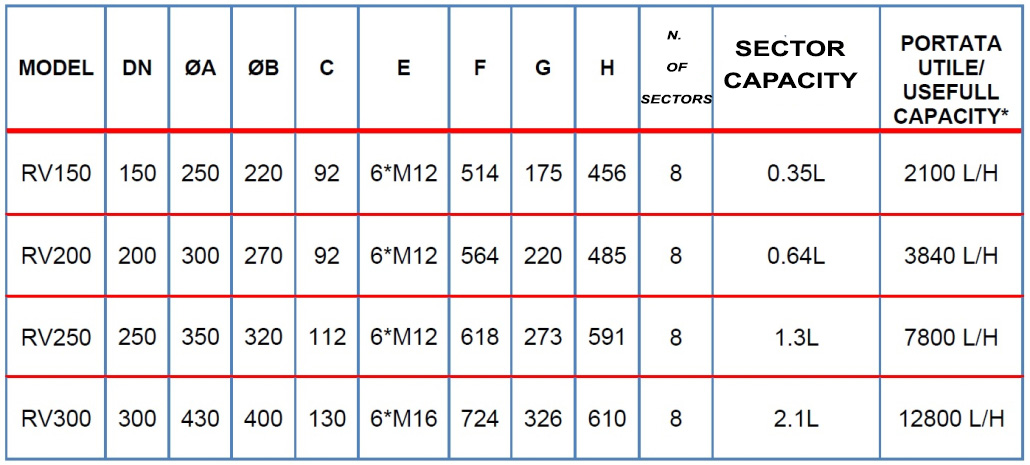

GIMAT rotary valves in the DN 150 – 200 – 250 – 300 version are operated by a gearmotor unit that can be controlled via an inverter if they have the function of dosing device – rotary feeders.

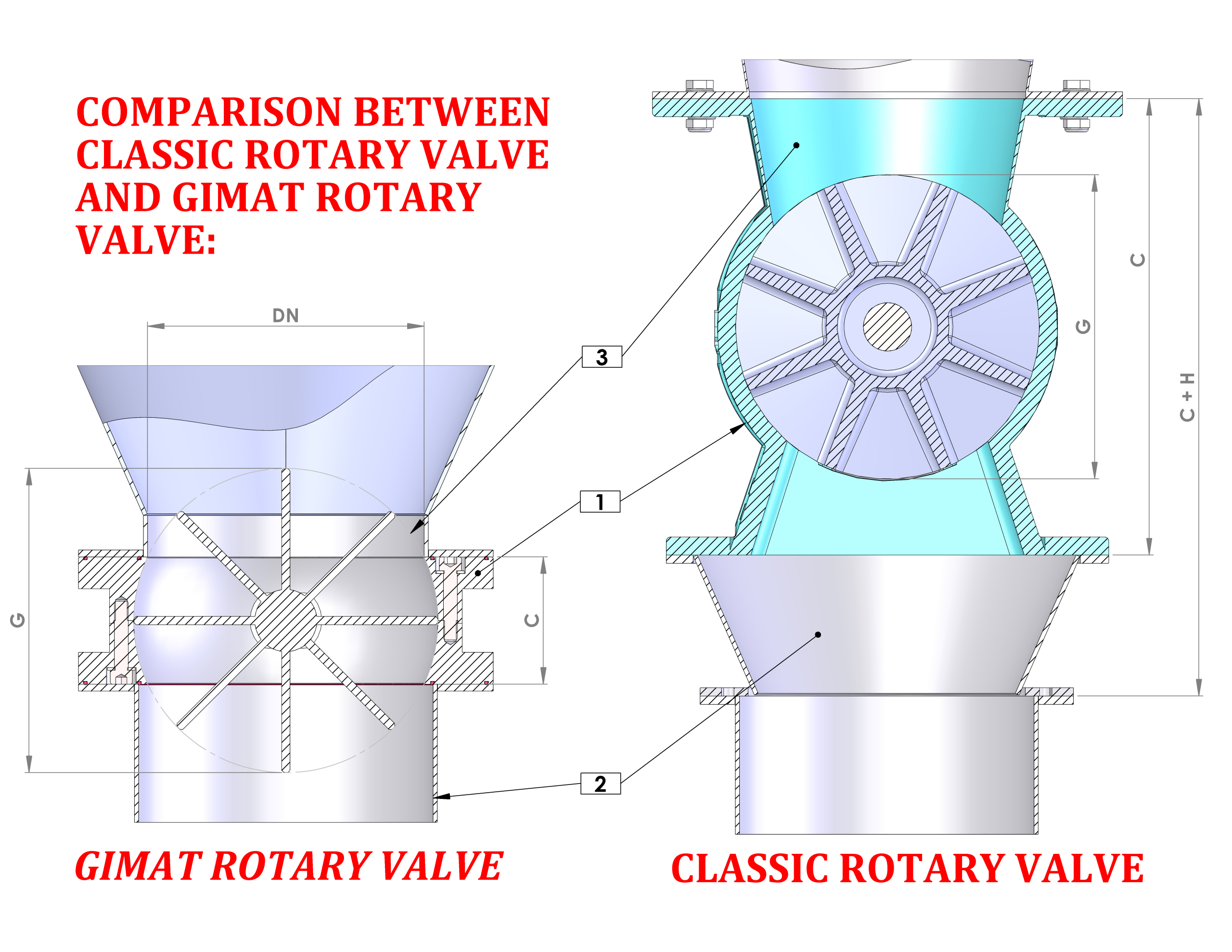

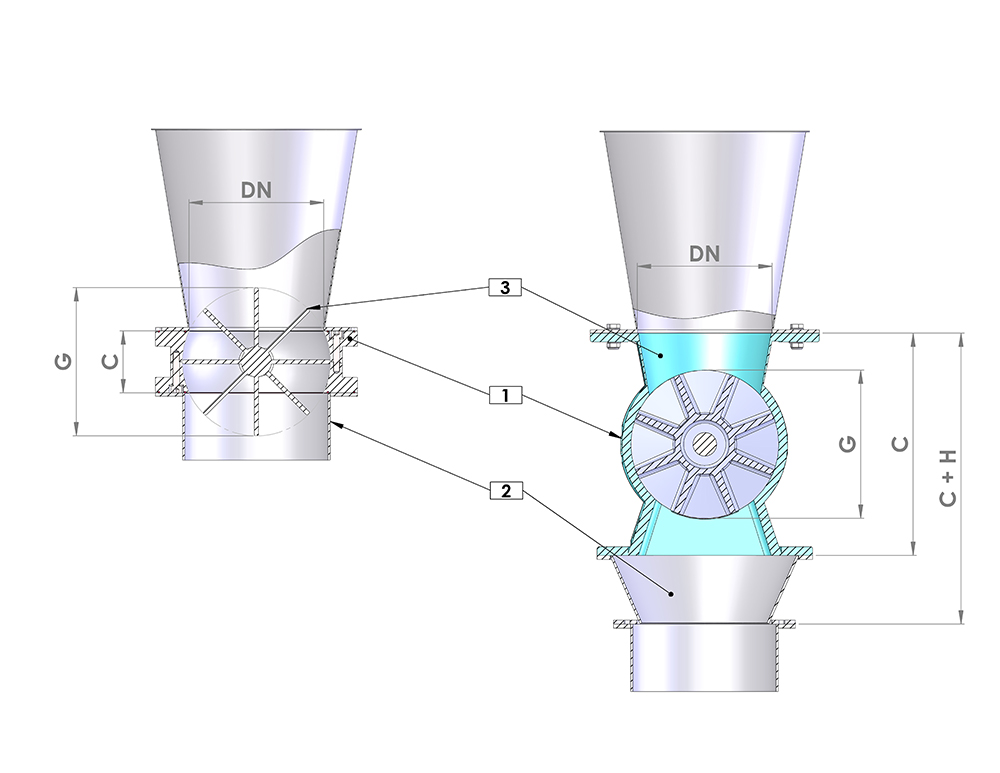

The compact valve body, low weight and protruding rotor facilitate cleaning and maintenance.

The rotary valves are also inserted below a cyclofilter inside a pneumatic conveying system in depression (max – 0.5 relative bar) or low pressure (max + 0.5 relative bar).

They are made entirely of AISI 304 or 316 stainless steel.

Thanks to the round flanges at the inlet and outlet, they are particularly suitable for vertical installations with minimum overall height, facilitating the construction of upstream and downstream connection carpentry.

Useful flow rates from 2 to 13 mᶾ / h.

| MODEL | (1) DIMENSIONS | (2) CONNECTION | (3) BRIDGE-BREAKING FUNCTION |

|---|---|---|---|

| GIMAT ROTARY VALVE | REDUCED DIMENSIONS MORE COMPACT AND LIGHTER TO FACILITATE OPERATIONS OF HANDLING AND MAINTENANCE | CONNECTION DIRECT UPSTREAM AND DOWNSTREAM WITH CIRCULAR FLANGE | ENTERING THE UPPER CARPENTRY, THE ROTOR OF THE STAR VALVE ALSO HAS A BRIDGE BREAKER FUNCTION TO FACILITATE MATERIAL WITHDRAWAL |

| CLASSICAL ROTARY VALVE | LARGE SIZE | A MANIFOLD IS NECESSARY TO ADAPT FROM A SQUARE TO A CIRCULAR FLANGE | THE ROTARY VALVE HAS NO BRIDGE-BREAKING FUNCTION. THERE IS A RISK THAT PASSING MATERIAL CAN FORM A BRIDGE OR FLOAT |

Flow rates from 2 to 13 mᶾ/h considering an average filling of 60% *

For your rotary valves inquiries in the UK, please contact Mr. Jonathan Kerr

Tel 01782 938400

Mob 07768 661749

Mail jk@gimatengineering.co.uk