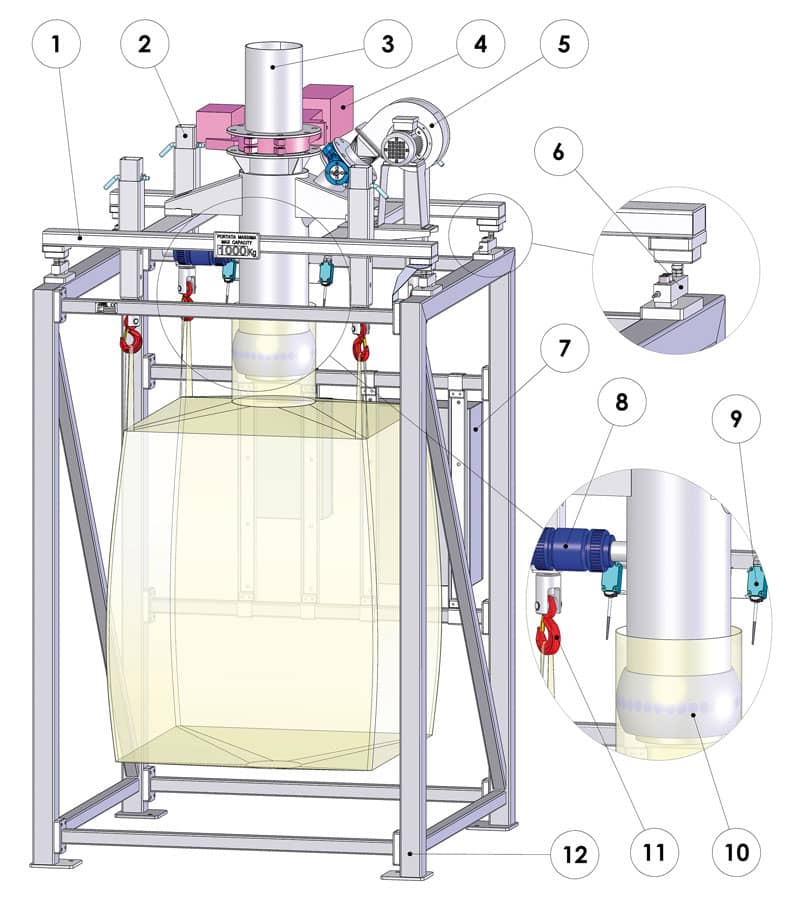

| Number | Description |

|---|---|

| 1 | UPPER SPIDER |

| 2 | VERTICALLY ADJUSTABLE UPRIGHT |

| 3 | DROP TUBE |

| 4 | SLIDE VALVE FOR INTERCEPTING PRODUCT SUPPLY |

| 5 | CENTRIFUGE FAN FOR INFLATING BULK BAG |

| 6 | LOAD CELLS WITH ANTI TIPPING ACCESSORY |

| 7 | CONTROL PANEL |

| 8 | SLEEVE VALVE TO CONNECT TO POWDER SUCTION SYSTEM |

| 9 | LEVER SWITCH |

| 10 | PNEUMATIC SLEEVE |

| 11 | SWINGING LIFT HOOKS |

| 12 | SUPPORT FRAME |

The solutions for filling and weighing bulk bags produced by GIMAT, are designed for suspending the bulk bags during the filling process in a safe way so as to prevent scattering powders in the environment.

The bulk bags lift loops are released from above once the bag has been filled, lifted off its base and placed on the pallet with the aid of a forklift or transpallet.

The bulk bag filling frame have four telescopic uprights so that the height of the structure can adjusted to adapt to different sized bulk bags.

In bulk bag filling processes we usually supply powder conveyors such as:

- flexible spiral or flexible screw conveyors

- screw conveyors

- pneumatic conveyors

Bulk bag fillers accessories

- Loading cells to weigh the product during filling and stop on reaching the desired weight

- Pneumatically inflatable rubber sleeve to provide a hermetic seal on the mouth of the bulk bag

- Possibility to inflate the bulk bag before filling to facilitate the distribution of the product on the inside, using an electric fan or pneumatic blower to create a venturi effect.

- Mechanically insulated vibrating platform at the base of the structure, for more compact filling, optimizing the bulk bag filling coefficient and eliminating excess air when necessary.

- Frame on height adjustable wheels, to move the structure easily

- Pneumatic product interception valve with instantaneous action to ensure precision dosage

Construction entirely in AISI 304 or 316 stainless steel

Configurations according to the ATEX directive 2014/34/UE can be supplied on request

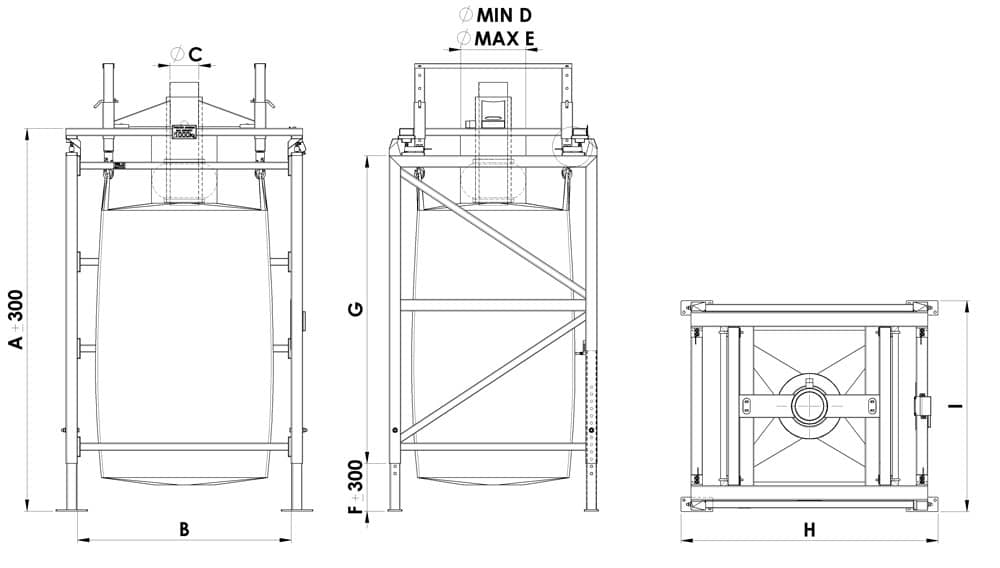

| Model | Max load (kg) | A (mm) | B (mm) | C (mm) | D (mm) | E (mm) | F (mm) | G (mm) | H (mm) | I (mm) |

|---|---|---|---|---|---|---|---|---|---|---|

| SSR 10/20 | 1000 / 2000 | 2900 | 1480 | 200 | 282 | 500 | 330 | 2130 | 1780 | 1460 |

Check out all our bulk bag handling applications in our YouTube channel

Bulk bag fillers applications examples

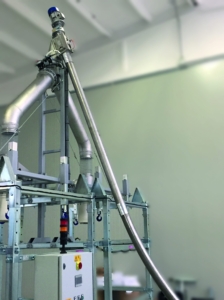

Bulk bag filling stations with optional weighing of contents on loading cells and filling via flexible screw. Sealing of the bulk bag opening via pneumatically inflatable sleeve and filling tube with double chamber for channeled venting of the particulate generated during filling. Vacuum on bulk bag opening achieved with electric centrifugal fan or pneumatic pump to facilitate bagging of powders.

Bulk bag weighting and filling equipment with rigid tube conveyor in rolled stainless steel and flexible spiral. Ideal solution for abrasive and/or very hot products. 2-Lane electro-pneumatic deviator to switch rapidly from one Bulk Bag filling station to the other without interruption of the production cycle.

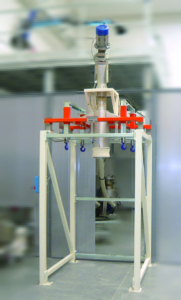

Bulk bag filling and weighing system, entirely constructed in AISI 304 stainless steel with automatic blower via centrifuge fan

Bulk bag filling on wheels with standing feet, adjustable via cranks

Palletizable bulk bag filling system

Bulk bag filling frame in painted carbon steel. Flow control via flexible spiral conveyor. Seal on mouth of bulk bag in simplified version with adjustable strap for granular products or pneumatically inflatable sleeve for powdered products

RELATED PRODUCTS