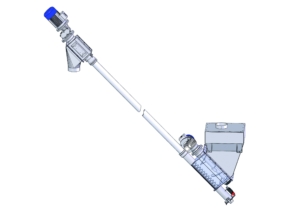

Flexible screw conveyors are widely used in the food, chemical, pharmaceutical and plastics industries for conveying; they provide equal efficacy for powders, granules, ground materials and mixtures.

They are made with a special wear-resistant hose in food-grade nylon PA12 with external diameters from 55 mm to 125 mm. The capacities are variable up to 10,000 kg/h, depending on the model chosen.

Flexible screw conveyor design

When designing a flexible screw, the actual capacity depends on:

• Rotation speed of the spiral and its model coefficient

• Tilt and type of infeed

• Nature of material conveyed

This kind of powder transfer system, despite its conceptual simplicity, must be appropriately engineered on the case by case basis: is the daily work of our technical department, to meet the specific functional requirements of the customer.

The main benefits of this kind of powder conveying system are:

• Homogenization of products previously mixed and dosed, without separation during movement, meaning to all effects that a process of continuous mixing must be ongoing

• The possibility of multiple combinations within systems

• Facilitated inclusion in existing systems because it is flexible and adaptable to on-site measurements

• Loading and discharge at any point of the line

• Ability to overcome height differences and cover long distances

• No pollution of the work environment because hermetically sealed and noiseless

• Low energy consumption in relation to the capacities obtainable

• Easy disassembly for cleaning and product change

• Minimum maintenance without the need for specialized labor by GIMAT

Upon request the flexible screw conveyor can be designed and built in conformity to ATEX Directive ATEX 2014/34/EU for Zone 2 – 22 and Zone 1 – 21 ![]()

GIMAT FLEXIBLE SCREW CONVEYORS PARTS AND MODELS

| Number | Description |

|---|---|

| 1 | MAXIMUM LEVEL SENSOR |

| 2 | MANIFOLD DISCHARGE |

| 3 | HOPPER MINIMUM LEVEL SENSOR |

| 4 | BRIDGE BREAKER UNIT |

| 5 | HOPPER FRAME |

| 6 | SAFETY GRID |

| 7 | HOPPER |

| 8 | ELECTROMECHANICAL VIBRATOR |

| 9 | ELECTRIC ANTI-VIBRATION DOWELS |

| 10 | FLEXIBLE CONVEYOR TUBE |

| 11 | OUTLET UNIT |

| Number | Description |

|---|---|

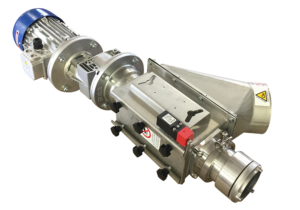

| 1 | ELECTRIC MOTOR |

| 2 | REDUCER |

| 3 | PULLING UNIT FOR FLEXIBLE SPIRAL |

| 4 | OUTLET |

| 5 | TUBE FIXING SLEEVE |

| 6 | DISCHARGE MANIFOLD |

| 7 | EXPANSION TERMINAL |

| 8 | SFS TYPE PICKUP PROBE |

| 9 | SAFETY MICRO SWITCH |

| 10 | FLEXIBLE SPIRAL TUBE |

| Model | Capacity ( litri / h)* | Diameter ext. (mm) | minimum radius (mm) |

|---|---|---|---|

| MAR 55 | 400 | 55 | 1400 |

| MAR 65 | 850 | 65 | 1600 |

| MAR 70 | 1250 | 70 | 1800 |

| MA 80 | 1800 | 80 | 2500 |

| MAR 90 | 2500 | 90 | 2800 |

| MAR 100 | 3500 | 100 | 3000 |

| MAR 110 | 4600 | 110 | 3800 |

| MAR 125 | 7500 | 125 | 4000 |

Infeed can be handled in various ways:

– Conveyed material: free flowing granular powder

– Continuous regular flow

– Apparent specific weight 1 kg/dm³;

– Initial infeed section with tilt α = 30°

– Rotary spiral with 580 rpm

(930 rpm applications are also possible).

* For the flow rate in kg / h multiply by the specific weight of your product

The transportation potentialities depend on several variables and therefore the tabulated values are understood as approximate; contact us for your specific application.

On our YouTube channel you can find examples of applications and complete systems engineered by Gimat in operation.

Examples of applications of flexible screw conveyors and accessory components

Flexible spiral conveyor with hopper on wheels, complete with vibrator and bridge breaker.

Wired control panel on machine with inverter for capacity adjustment

Horizontal flexible screw conveyor with multiple discharge distribution to different infeeds

located along the line

Solution with flexible elevator screw that draws from a Bulk Bag Emptying Station and supplies a horizontal spiral with the function of distributor.

Storage in conical-cylindrical hopper with flat-bottomed extractor and dual outlet. Infeed through two flexible screws of which one is a single horizontal conveyor and one functions as extractor and elevator for vertical lift in limited installation space.

Flexible screw conveyors with infeed from several levels of a circular vibrating screen.

Bulk Bag emptying, multistage screening, powder conveying and Bulk Bag filling

Flexible screw conveyor for emptying mixer and loading mixtures of grains into a buffer containing the same material, without demixing.

Resin conveyor and doser in a dissolver using a single flexible screw conveyor system.

Flexible screw conveyors with infeed from a bag cutting hopper complete with suction hood for the elimination of particulate generated during emptying

Flexible screw conveyors entirely on wheels in different configurations of discharge heights, hourly capacity and construction materials.

Bulk Bag emptying, conveying and dosing of macro-components with flexible screw conveyors, gravimetric dosing of micro-components and mixing with horizontal ribbon mixer.

Bulk Bag Emptier, Conveyor and Doser for pellets, with Grinding, Screening and filling of Bulk Bags with the powder produced in the process.

.