Bulk bag conditioners design

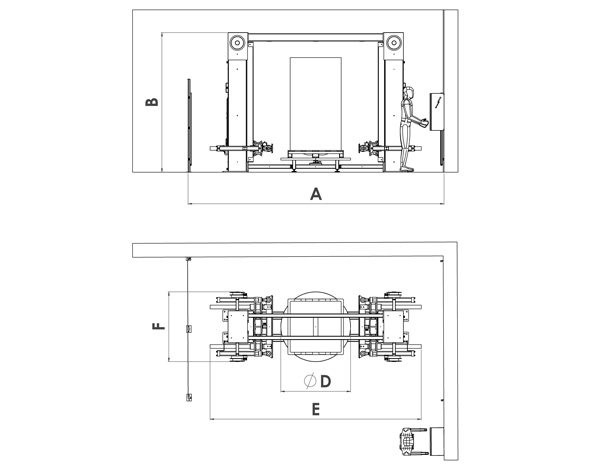

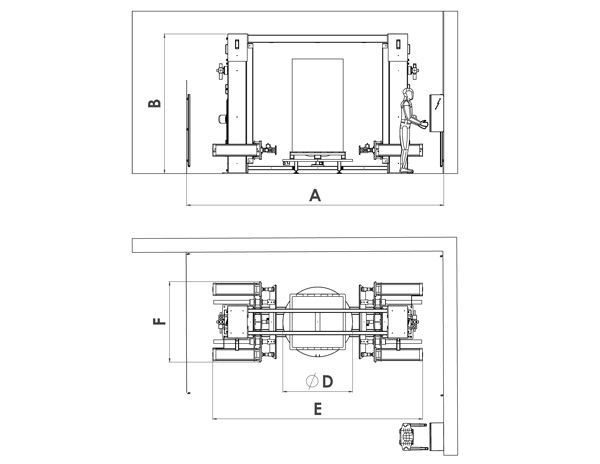

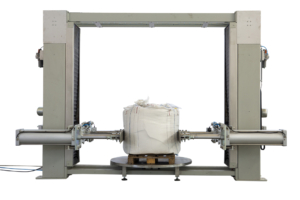

The pressing plates are operated horizontally by a pair of hydraulic or pneumatic pressers, specially configured to generate adequate specific pressure on the bulk bag without breaking it.

Customers will decide which is the best solution depending on their needs. If there is already a source of compressed air in the plant, the pneumatic solution is, of course, preferable because easier to maintain, economical and, if necessary, can be certified for ATEX zone 2-22 with minimum additional cost, compared to the hydraulic version.

Hydraulic and pneumatic versions

Both the hydraulic and the pneumatic solution can always guarantee the necessary and identical power source even for the more hardened big bags.

The action of compression and massage is carried out on all four sides of the bulk bang thanks to the pneumatic pallet wheel that permits rotation by 90° and along all the height thanks to the automatic vertical movement of the two pressing plates.

The bulk bag is loaded onto the special pallet wheel with a forklift or electric transpallet, making it possible to install the bulk bag conditioner even in narrow or elevated spaces.

The pressing system is anchored to a rigid self-supporting closed structure framework tested with Finished Element Analysis, in which all the reactions of the powerful forces generated during bulk bag reconditioning can be safely discharged.

The operating cycle can be either manual or fully automatic and programmable by touch screen with customized recipe depending on the type of bulk bag. The automation is achieved with Siemens S7-1200 PLC and integrated in the industry 4.0 environment with remote connection for servicing.

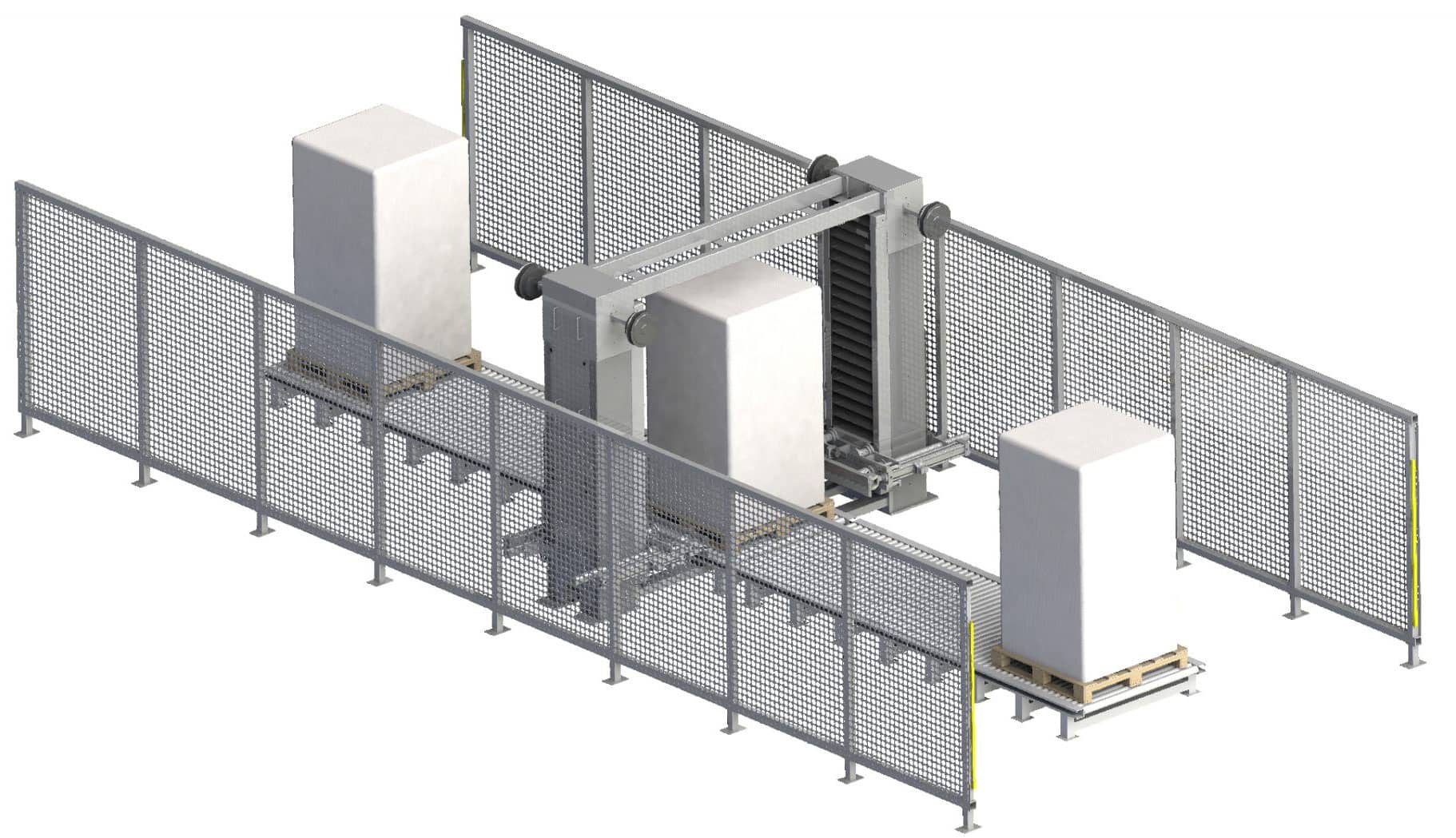

The machine is protected from crushing risk for the operator and is certified CE thanks to an integrated system of fixed and optical barriers with a special safety and monitoring control center with protection certified SIL 2 (EN 62061) Cat.3 PLd ( EN ISO 13849-1). On request, guards can be provided and closure of the four sides via three fixed and one openable gate equipped with an interlocking microswitch.

The reconditioning capability of the bulk bag conditioner in either the hydraulic or pneumatic version is around 8-10 bulk bags/hour. To optimize the conditioning cycle and automate it, the bulk bag conditioner can be integrated with an automated roller conveyor as shown in the photograph at the top of this product sheet. In this way it is possible to achieve a productivity of 12 bulk bags (1 cu. m.)/hour.

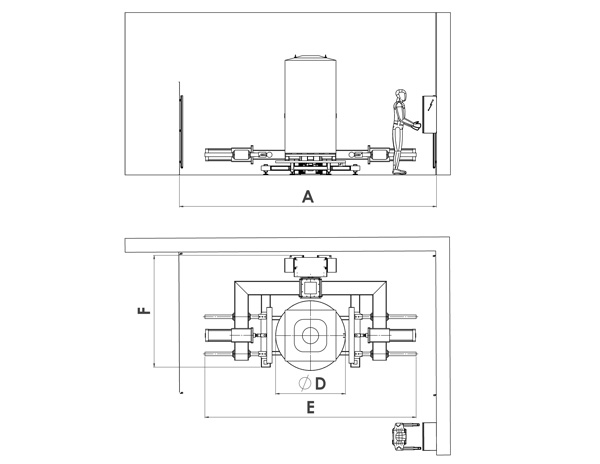

C-shape pneumatic version

To complete the range offered, a less powerful but more compact “C” solutions has been introduced recently. It is economical and easy to install, completely pneumatic as regards the Bulk Bag conditioning plates. The vertical movement of the plates can be either pneumatic or by linear electric actuator if higher performance is necessary.

Every pressing plate is driven, in this case, by a single pneumatic piston with lateral guides, rather than by a double piston. To overcome the problem of the lesser pressure exercised on the bulk bag, the pressing tool has been altered to make it lower and give it a rounded shape so as to obtain the same specific pressure on the bulk bag during conditioning.

The new tool has proven highly efficient with gentle action on the bulk bag but, because the area involved in each pressing is smaller, more time is required to complete the full conditioning cycle. This tool can also be used to condition bulk bags that are not quite full.

The performance of the bulk bag conditioner “C Shape” is 4-5 bulk bags/hour

Configurations according to the ATEX directive 2014/34/UE can be supplied on request